Time for me to start making stuff again… It has been FAAARRRR too long. I whipped this together at lunch time today, simple 3 channel PWM using TIP142s. It is driving a 30W RGB LED at 30V, and at peak it runs around 1.8A of draw.

My goal

Time for me to start making stuff again… It has been FAAARRRR too long. I whipped this together at lunch time today, simple 3 channel PWM using TIP142s. It is driving a 30W RGB LED at 30V, and at peak it runs around 1.8A of draw.

My goal

My anti backlash ball screws, rails and linear bearings arrived! This CNC table is going to be massive!

30W RGB Led Test - Before I pack all this up tomorrow I decided to test out one of the 30W RGB LEDs I got to do accent lighting for my new office. It is powered by 3 individual drivers that accept PWM input to drive the output. Each LED

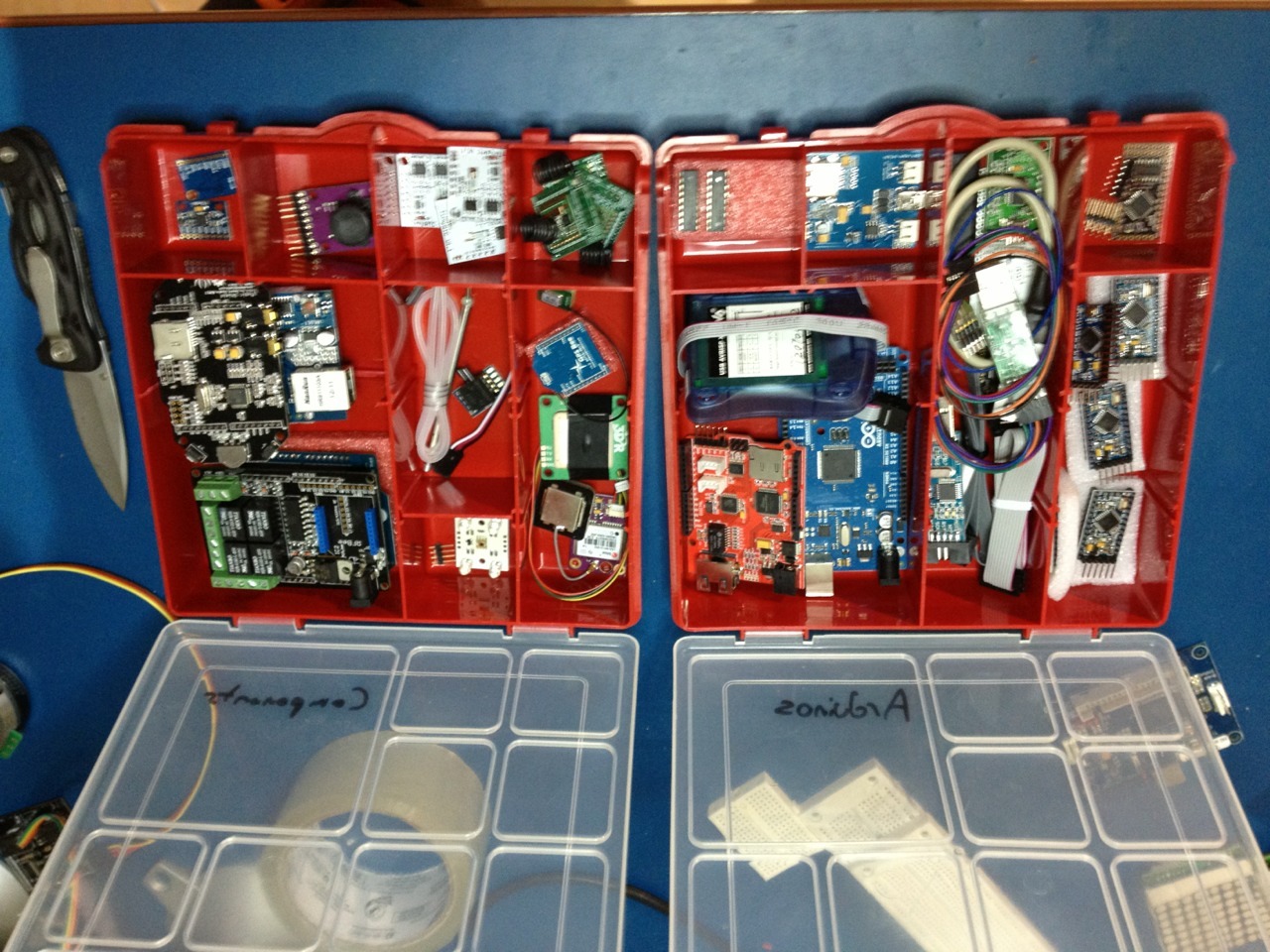

Packing my components for our upcoming move! It’s nice to be a little organized for once…

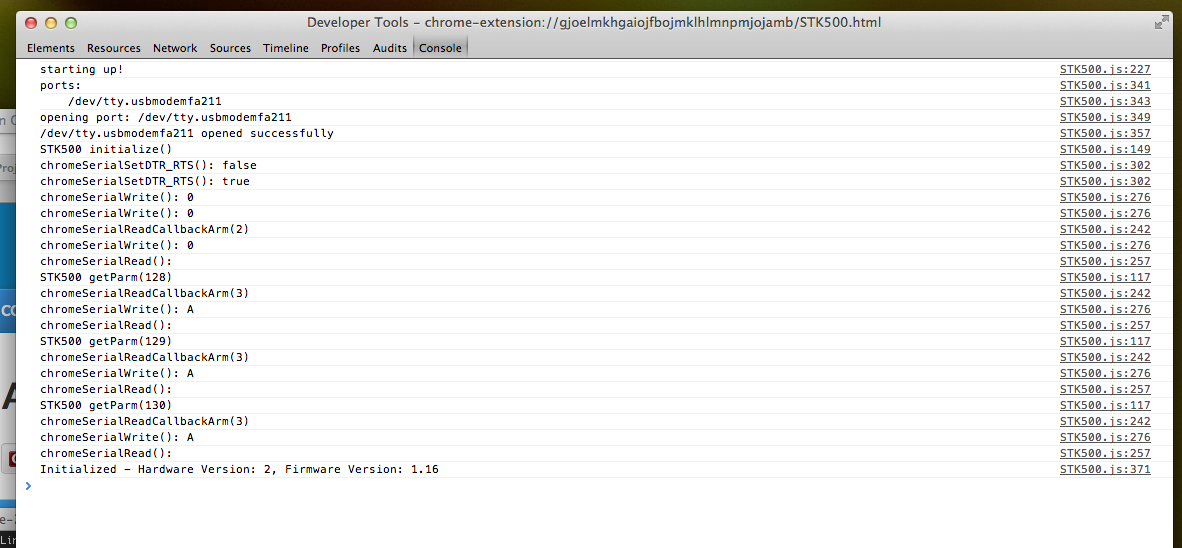

Another refactor to have object based callbacks defined, with {success: , error:} etc.

Finished implementing the initialization process. Everything returns data as expected, which is great!

Go check out the source: https://github.com/dchote/jsSTK500

jsSTK500 update! Initialization is now working! I refactored the code to better work the way you would expect it (with callbacks etc).

Go check out the source: https://github.com/dchote/jsSTK500

After a bit of haxing tonight I have the skeleton object layed out, and the initial serial->protocol logic defined.

I am now basing this entirely off the avrdude implementation for simplicity sake (its a lot easier to read).

The jsSTK500 project is hosted on github here.

NOTE: This

30W RGB LED. A few weeks ago i ordered 4 30W RGB LEDS and drivers. They arrived today, and they are HUGE! Here is a size comparison against a Pinoccio Scout and my business card.

I am in the process of writing an arduino programmer entirely in javascript using google chrome’s serial API. I am fairly sure this is going to work, as I am implementing stk500 from a java implementation I found as an example, referencing the avrdude code along the way.

I am trying to find a good way to print out a part design and transfer it somewhat permanently on to sheet aluminum. This is until I can afford a desktop cnc, and would allow me to be a lot more precise in my hand fabrication of parts. Any ideas?